Viral Vector Process Development

자세히 보기

간단히 보기

Upstream bioprocess development for viral vector production

자세히 보기

간단히 보기

Plasmid production

In the context of viral vector production, plasmids can be adapted to contain the instructions for producing viruses with specific genomes. Through standard plasmid cloning, viruses can therefore be engineered to contain important genes for either gene therapy or vaccination purposes. Viral vectors can be used as a powerful tool for the delivery of this genetic information into mammalian cells. During the plasmid production stage, plasmids are either constructed in the laboratory or selected from existing stock. The type and number of plasmids you require will depend on the viral vector you choose to use and whether you intend to use transient or stable cell lines. Learn more about plasmid production in our webinar!

Cell expansion and virus production

자세히 보기

간단히 보기

Cultivation of adherent cells

Growing adherent cells relies on a growth support matrix. Conventionally, 2D culture systems like flasks and dishes have been used, but as technology has evolved, cultivation in bioreactors provides an alternative option that exploits the benefits they offer in terms of process control and scalability. The use of microcarrier-based culture systems and packed-bed bioreactors filled with Fibra-Cel® Disks are options for cultivating adherent cells in bioreactors.

Fibra-Cel® Disks

자세히 보기

간단히 보기

Microcarrier-based cell culture systems

자세히 보기

간단히 보기

Plasmid transfection, viral vector production, and harvest

자세히 보기

간단히 보기

Learn more about transient and stable transfection

자세히 보기

간단히 보기

자세히 보기

간단히 보기

자세히 보기

간단히 보기

Bioprocessing for AAV vector production

Cells will need to be harvested and the viral vectors isolated for characterization and quantification. An important part of this process is determining the ratio of viral vectors with genomes to those without, known as the full/empty ratio. This can be done using methods including ELISA, electron microscopy, analytical ultracentrifugation (AUC), and high-pressure liquid chromatography (HPLC), each of which has benefits and limitations of its own. For information on AAV vector production workflow in a bioreactor, check out this application note!

Eppendorf upstream bioprocessing solutions for cell culture

자세히 보기

간단히 보기

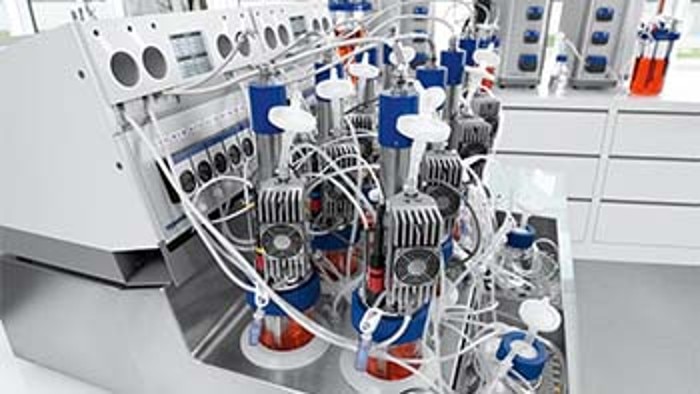

Small scale bioreactor systems

The DASbox® Mini Bioreactor System and DASGIP® Parallel Bioreactor Systems for cell culture applications are well suited for process development and downscaling approaches.

- Working volume range: 100 mL to 1.5 L

- Parallel processing of up to 24 bioreactors

- Compatible with glass bioreactors and BioBLU® Single-Use Bioreactors

- Suitable for suspension cell culture and cell culture on microcarriers

Bench scale bioreactor systems

The bench scale bioreactor systems BioFlo® 120 , BioFlo® 320 , and SciVario® twin facilitate process development and scale-up

- Working volume range: 200 mL to 40 L

- Compatible with glass bioreactors and BioBLU® Single-Use Bioreactors

- Suitable for suspension cell culture and cell culture on microcarriers

- Compatible with packed-bed bioreactors filled with Fibra-Cel® Disks

Large scale bioreactor systems

For cell cultivation at large scale Eppendorf offers the BioFlo® 720 bioreactor control system.

- Offers scalability from 50 L to 2000 L

- Compatible with the BioBLU® 50c Single-Use Bioreactor

- Compatible with Thermo Scientific® HyPerforma® Single-Use Bioreactors

Contact us

자세히 보기

간단히 보기